Delete DD15 Freighliner: DETROIT DIESEL DPF EGR DEF DELETE | DPF DELETE TUNER

DPF, EGR, and DEF removal services for Detroit Diesel engines. Restore engine power, improve fuel efficiency, and eliminate emissions-related failures. Remote ECM tuning via TeamViewer for fast, professional service. Ideal for off-road, export, and deleted-use applications. Trusted solutions to keep your Detroit Diesel engine running strong, reliable, and maintenance-free.

Welcome to Detroit Diesel DPF EGR DEF Delete Tuning Service, your go to for Detroit Diesel engine optimization. We specialize in professional removal and tuning services for DEF, EGR, and DPF delete tuning components like the Diesel Particulate Filters (DPF), Exhaust Gas Recirculation (EGR) systems, and Diesel Exhaust Fluid (DEF) components for heavy duty truck owners and operators.

Our expert team uses advanced ECM reprogramming to deliver reliable and efficient solutions. By removing restrictive emissions systems we increase engine power, fuel efficiency and overall performance. With reduced maintenance costs and downtime you can focus on keeping your business running and saving long term. Each modification is meticulously crafted to ensure the durability of your vehicle, guaranteeing long-term performance and reliability.

At Detroit Diesel DPF EGR DEF Delete Tuning Service we are committed to safe, precise and professional service. Our tuning solutions are for off-road and export applications so we can meet specific use cases. With years of experience and deep knowledge of Detroit Diesel engines we guarantee results.

Unleash the power of your Detroit Diesel engine with our trusted tuning services. Contact us today to learn more, schedule a consultation and see the difference in power, performance and reliability. Your truck’s transformation starts here!

Remote Tuning Requirements for Detroit Diesel Engines

To ensure a successful and efficient remote tuning session for your Detroit Diesel engine, please ensure you have the following equipment and software prepared before our scheduled appointment. These requirements are essential for establishing a stable connection to your vehicle’s Engine Control Module (ECM) and allowing our certified technician to perform the calibration process safely and accurately.

RP1210-Compliant Diagnostic Adapter

A high-quality diagnostic interface is crucial for communicating with your Detroit Diesel ECM. We support all major RP1210-compliant adapters including the Nexiq USB Link, Cummins Inline, DPA5, Noregon JPRO, or equivalent devices. This hardware serves as the vital bridge between your laptop and the vehicle’s diagnostic port, enabling the precise programming required for performance modifications.

Windows Laptop with AnyDesk Installed

You will need a Windows-based laptop (Windows 10 or 11 recommended) with AnyDesk remote access software pre-installed. This application allows our technician to securely connect to your system and perform the necessary programming steps in real-time. Ensure your laptop is fully charged or connected to power throughout the session to prevent interruptions.

Detroit DiagnosticLink 8.x or Higher with Full Access

A current version of Detroit DiagnosticLink (version 8.x or newer) must be installed with full system capabilities, often referred to as “10-10-10” access. This specific licensing level provides the read/write permissions essential for ECM calibration changes, going beyond basic diagnostic functionality to enable comprehensive tuning modifications.

Stable Internet Connection & Reliable Power Source

A strong, stable internet connection is mandatory for both parties to maintain uninterrupted communication during the programming process. Additionally, we strongly recommend connecting a battery charger/maintainer to the truck’s electrical system to ensure consistent voltage throughout the ECM flashing procedure, preventing potential damage from power fluctuations.

By verifying that these requirements are met before our session, we can ensure a smooth, secure, and successful remote tuning experience for your Detroit Diesel engine.

SELECT YOUR ENGINE MODEL

DETROIT DD13

See the list of DETROIT DD13 engines and solution options that we have for you.

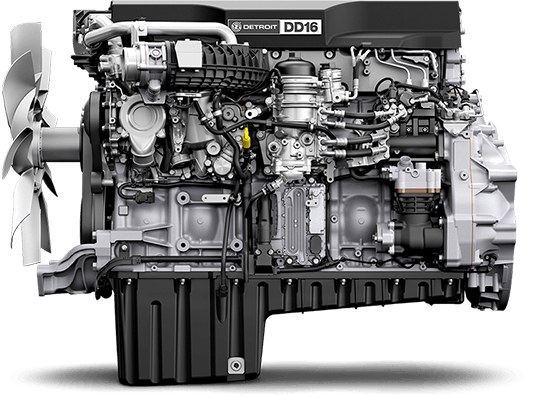

DETROIT DD16

See the list of DETROIT DD16 engines and solution options that we have for you.

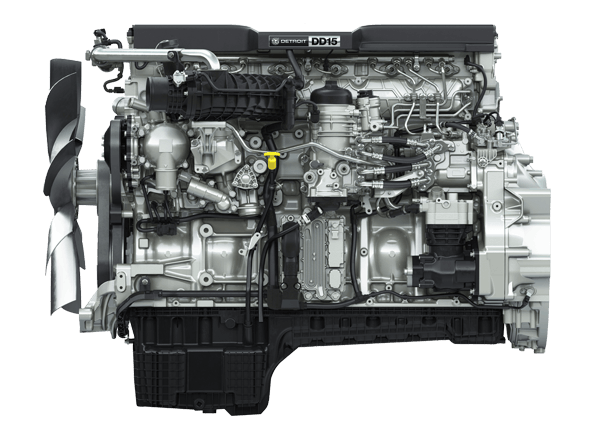

DETROIT DD15

See the list of DETROIT DD15 engines and solution options that we have for you.

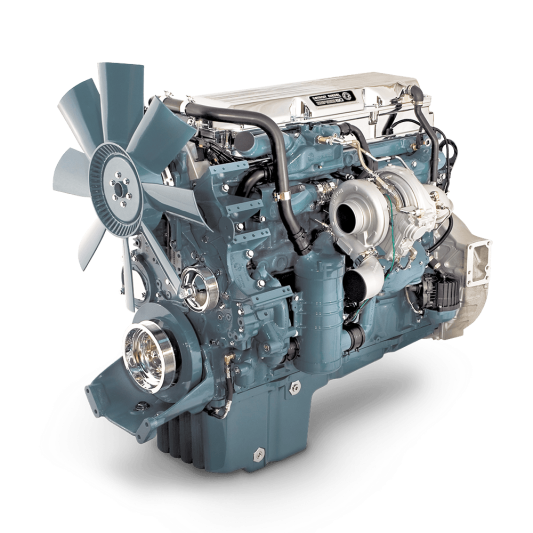

DETROIT SERIES60

See the list of DETROIT SERIES60 engines and solution options that we have for you.

Tuning: Detroit Diesel Dpf Delete

Diesel particulate filter (DPF) removal, commonly referred to as “DPF Delete,” is a comprehensive modification procedure applied to Detroit Diesel engines to remove the particulate filtration component from the exhaust aftertreatment system. This process involves physical hardware modification and electronic software recalibration to address operational issues inherent to the DPF system, primarily on engines from the DD13, DD15, DD16, and EGR Series 60 platforms.

The primary function of the DPF is to trap soot particles from the exhaust stream to meet EPA-mandated emissions standards (post-2007). As the filter becomes loaded with soot, it must undergo a periodic regeneration cycle. During this process, the Engine Control Module (ECM) initiates a post-combustion fuel injection, either into the cylinder or directly into the exhaust via a dedicated proportioner, to raise the exhaust gas temperature to approximately 538°C (1000°F).

This incinerates the trapped soot in a smaller volume of residual ash. While effective for emissions control, these regeneration cycles are a significant source of operational inefficiency. They consume additional fuel, disrupt vehicle work cycles for up to 40 minutes, and subject the turbocharger, exhaust manifolds, and valves to extreme and repeated thermal stress, which could affect long-term reliability.

The physical removal process involves dismantling and unscrewing or cutting the DPF cartridge from the exhaust system. Typically replaced with a section of straight pipe or a high-performance muffler.The engine control module (ECM) will immediately detect the absence of the DPF and its associated differential pressure sensors, triggering critical fault codes and reducing engine power to limp-home mode.

Therefore, the second crucial phase is the electronic removal of the DPF system from the engine management software. This is achieved by updating the ECM with customized performance settings. This specialized software performs several key functions: it permanently disables all active and passive regeneration cycles, removes the DPF pressure sensor monitoring algorithms, and recalibrates the fuel injection maps to account for the eliminated exhaust back pressure.

PROFESSIONAL SUPPORT

Tuning: EGR Delete Detroit Diesel

Exhaust gas recirculation (EGR) removal is a major modification procedure for Detroit Diesel engines, designed to eliminate the operational and mechanical complications associated with the EGR system. This process, applicable to key engine platforms such as the EGR-equipped Detroit Diesel DD13, DD15, DD16, and later Series 60 models, involves the physical removal of EGR components and a fundamental recalibration of the engine’s electronic control module (ECM). The primary technical objective is to prevent the recirculation of soot and exhaust contaminants into the engine’s intake stream.

The primary function of the EGR system is to reduce the formation of nitrogen oxides (NOx) by lowering combustion temperatures. This is achieved by directing a metered portion of the exhaust gases from the exhaust manifold, through an EGR cooler, and back to the intake manifold. While effective for emissions compliance, this process presents several inherent problems. Recirculated exhaust gases contain soot, unburned hydrocarbons, and acidic compounds.

Over time, this causes significant carbon buildup in the intake system, on the intake valves, and particularly in the EGR cooler and the valve itself. This buildup restricts intake airflow, reduces engine efficiency, and can cause erratic EGR valve operation. Furthermore, in applications with high-sulfur fuel or prolonged idling, the combination of these contaminants with condensation can form highly corrosive acids that degrade the EGR cooler, which can lead to coolant leaks in the intake or cylinders, potentially causing severe engine damage due to hydrolock.

The EGR removal process consists of two stages. The first is physical and involves removing the EGR valve, the EGR cooler, and associated piping. The system is shut down by blocking the exhaust and intake manifold ports with machined block-off plates to keep the system sealed. This physically prevents the rerouting of exhaust gases.

However, physical removal alone is not enough. The engine’s electronic control module (ECM) is programmed to actively control and monitor the EGR system. If it detects the absence of EGR components or an incorrect flow reading, it will log critical fault codes and reduce engine power to protect the system. Therefore, the second, and most critical, step is electronic. The Detroit Diesel engine’s ECM must be flashed with a custom calibration file, often called a “clear tune.” This software removes all EGR-related commands, disables EGR valve actuator controls, and removes EGR flow monitoring parameters from the diagnostic logic.

Tuning: Detroit diesel DEF,SCR Delete

Diesel exhaust fluid (DEF) and selective catalytic reduction (SCR) system removal is a component removal and calibration modification process for Detroit Diesel engines. This procedure, applicable to DD13, DD15, DD16, and Series 60 engines equipped with advanced aftertreatment, involves the physical removal of SCR components and the electronic deactivation of the DEF dosing system. The primary objective is to eliminate the operational burden, consumables costs, and failure points associated with the NOx reduction system.

The SCR system is the final stage of the modern emissions control process. Its function is to break down nitrogen oxides (NOx), a byproduct of high-temperature combustion, into harmless nitrogen and water vapor. This chemical reaction is facilitated by a catalyst within the SCR canister and requires a precise reductant: DEF. DEF is a mixture of urea and deionized water stored in a dedicated tank and injected as a fine mist into the exhaust stream before the SCR catalyst.

Engine control modules meticulously monitor the quality and quantity of the DEF. If the DEF tank level is depleted, quality is compromised, or any system component fails, the engine’s electronic controls will issue a series of increasingly frequent warnings, ultimately resulting in a drastic reduction that drastically limits vehicle speed and power to ensure regulatory compliance.

Physical removal involves disabling the DEF system. This includes removing the DEF injection nozzle from the exhaust pipe, removing or rerouting the DEF supply lines, and often removing the DEF tank and metering pump.

The second part involves installing a custom calibration file in the engine’s electronic control module (ECM) and aftertreatment control module (if standalone). This “erase configuration” performs several essential functions: it permanently disables all commands to the metering pump and DEF injector, removes the monitoring algorithms for the DEF tank level and fluid quality sensors, and clears the NOx sensor monitoring and diagnostic trouble codes associated with the SCR system.

The software recalibrates the engine to operate without DEF-dependent aftertreatment, avoiding power reduction strategies and ensuring normal engine operation.

The immediate technical benefits of this elimination are the elimination of DEF-related costs, both for the fluid itself and for the maintenance of vulnerable components such as heated lines, pumps, and injectors, which are prone to freezing or clogging. It also eliminates the risk of being immobilized due to a DEF system failure.

How much does it cost to delete a DD15 engine?

The cost of deleting a DD15 engine can vary significantly depending on several factors. One of the primary considerations is the year and model of the Detroit truck equipped with the DD15 engine. Different models and production years may have varying requirements for the deletion process, which can affect the overall cost. Additionally, the software version of the engine’s ECM plays a crucial role in determining the price, as certain versions may require more complex tuning and adjustments.

For an accurate estimate tailored to your specific vehicle, it is recommended to get in touch with our expert team. We can provide a detailed assessment based on your truck’s unique specifications and offer a customized solution that fits your needs. Don’t hesitate to contact us for more information and to schedule a consultation to discuss the best options for optimizing your Detroit Diesel engine’s performance.

Contact Us

+51966080192

DPF SOLUTIONS