CATERPILLAR | DPF DELETE TUNER

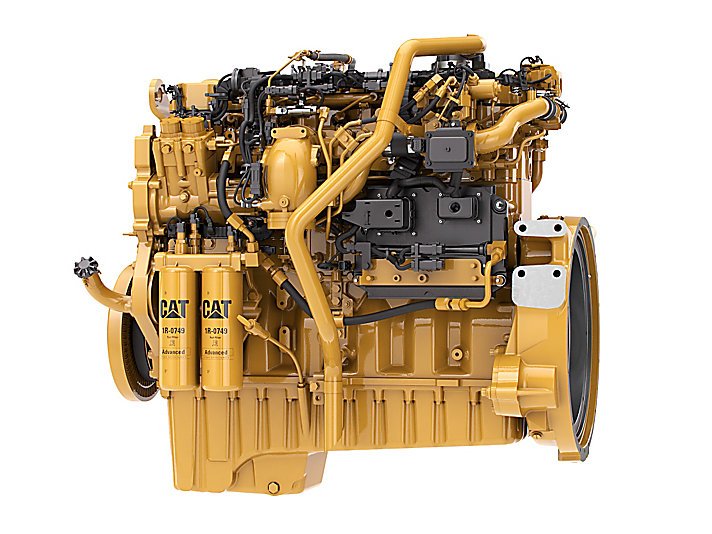

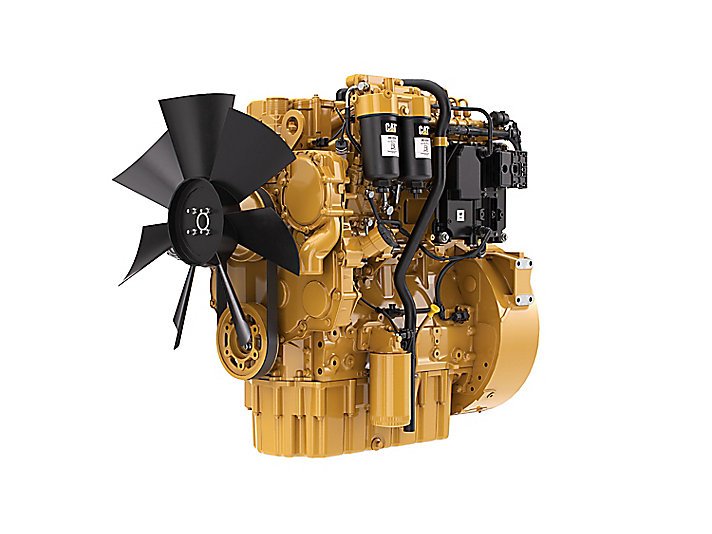

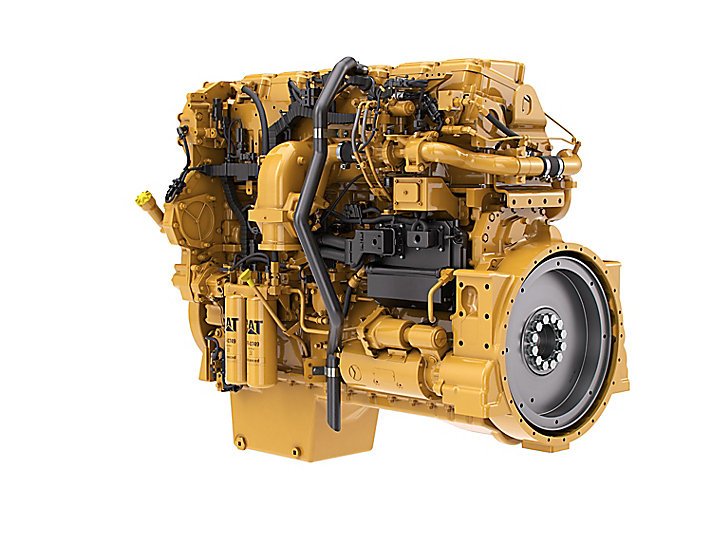

At Dpddelete Tuner, we specialize in bringing out the best in your Caterpillar engine. Our tailored deletion services focus on optimizing performance and durability. Let our experienced team take your Caterpillar engine to the next level of efficiency and power.

Introduction to DPF Delete Technology

The introduction of DPF delete technology has revolutionized the way diesel engines operate, particularly in Caterpillar models. By increasing power, engine owners can improve fuel economy and reduce maintenance costs. A caterpillar dpf delete kit is a popular solution for many diesel engine owners, as it allows for the removal of the DPF filter, which can become clogged and cause engine damage. In this section, we will explore the importance of DPF delete technology and its benefits for modern engines.

Overview of DPF Delete and Its Importance in Modern Engines

DPF delete is a process that involves removing the diesel particulate filter from a diesel engine, allowing for improved fuel economy and increased power. This is particularly important in modern engines, where the DPF filter can become a bottleneck, restricting engine performance. By eliminating the DPF, engine owners can enjoy improved fuel efficiency, reduced emissions, and increased power. A dpf delete kit is a simple and effective way to achieve this, and can be installed on a variety of Caterpillar models, including cat skid steer and caterpillar engine models.

Understanding DPF Systems

To understand the importance of DPF delete technology, it’s essential to understand how DPF systems work. A diesel particulate filter (DPF) is a device designed to capture particulate matter and reduce emissions from diesel engines. However, DPFs can become clogged, requiring regular regeneration, which can be time-consuming and costly. In this section, we will explore the role and functionality of DPF in Caterpillar engines and how a caterpillar dpf delete kit can improve engine performance.

The Role and Functionality of DPF in Caterpillar Engines

The DPF filter plays a critical role in reducing emissions from Caterpillar engines. However, it can also become a bottleneck, restricting engine performance. The DPF filter works by capturing particulate matter and reducing emissions, but it requires regular regeneration to function effectively.

This can be a time-consuming and costly process, particularly for engine owners who rely on their vehicles for work or transportation. By installing a dpf delete kit, engine owners can eliminate the need for regeneration, improving fuel economy and increasing power. This is particularly important for cat engines, which are designed to provide high levels of power and efficiency.

SELECT YOUR ENGINE MODEL

CAT C9 C9S

See the list of CAT C9 C9S engines and solution options that we have for you.

CAT C15 SDP

See the list of CAT C15 SDP engines and solution options that we have for you.

CAT C13 LEE

See the list of CAT C13 LEE engines and solution options that we have for you.

CAT C7 C7S

See the list of CAT C7 C7S engines and solution options that we have for you.

CAT C15 MXS NXS BXS

See the list of CAT C15 MXS NXS BXS engines and solution options that we have for you.

CAT C13 KCB

See the list of CAT C13 KCB engines and solution options that we have for you.

CAT C11KCA

See the list of CAT C11KCA engines and solution options that we have for you.

CAT C4.4, 316E

See the list of CAT C4.4, 316E engines and solution options that we have for you.

CAT 6NZ/2WS/MBN

See the list of CAT 6NZ/2WS/MBN engines and solution options that we have for you.

Remote Removal Service on Caterpillar Engines

Caterpillar DPF Delete and CGI Removal: Proven Remote Services for Best Engine Performance

Caterpillar engines are powerful and efficient, especially in heavy duty applications like construction, mining and agriculture. Injectors in OEM DPF regeneration systems create the necessary heat for emissions management, but our remote services offer a simpler, maintenance-friendly solution. But emissions regulations often hinder their performance due to the inclusion of components like Diesel Particulate Filters (DPF) and CGI (Clean Gas Induction) systems.

For many owners these components reduce performance and are costly to maintain. Luckily services like Caterpillar DPF delete and CGI removal is a solution to get back your engine to optimal performance. This guide will explain how these services work, what are the benefits and how remote ECM tuning is changing the game.

Caterpillar DPF Delete and CGI Removal

The Diesel Particulate Filter (DPF) is a device that traps and reduces the amount of soot emitted by diesel engines. Vehicles must be traveling at high speeds in order to reach the required temperatures for DPF regeneration. While it helps reduce emissions the DPF often requires maintenance due to soot buildup which can lower fuel efficiency and cause engine performance issues.

The CGI (Clean Gas Induction) system is another emissions related component found in Caterpillar engines and controls certain aspects of the engine’s combustion.Removing both the DPF and CGI involves altering the Engine Control Module (ECM) software which controls how the engine runs. By disabling these systems through software adjustments operators can eliminate recurring faults and maximize engine output.

Proven Solutions for Caterpillar Engines

In my experience we’ve provided 100% proven solutions for removing emissions related components like DPF in Caterpillar engines. Our services will have your engine running at peak performance with no emissions related faults and we can do this remotely so you have flexibility and convenience.

Benefits of Removing the DPF and CGI Systems

There are several reasons why Caterpillar engine owners choose to delete the DPF and CGI systems:

Better Performance: By removing the DPF the engine can breathe more and exhaust flows better and gains horsepower. This is especially important for engines under heavy load or in industries where performance is critical.

Fuel Efficiency Gains: The regeneration process to clean the DPF consumes fuel and reduces overall efficiency. Removing the DPF eliminates this process, making the engine breathe more easily and improving fuel efficiency, ultimately making the fuel last longer.

Less Maintenance Costs: DPF systems require regular maintenance or replacement, both of which can be expensive. Removing the DPF means avoiding these costs and preventing downtime caused by clogged filters or sensor failures.

Optimized Engine Tuning: Remote DPF and CGI delete services often include custom ECM tuning which allows the engine to run more efficient. This tuning can be adjusted for performance gains so the engine runs smooth without fault codes.

No Derates or Fault Codes: After the DPF and CGI systems are disabled remote ECM tuning ensures the engine will not derate (reduce power) when the emissions components fail. The software adjustments will also prevent any fault codes from showing up so you have peace of mind.

How Remote ECM Tuning Works

Remote ECM tuning is a very efficient way to modify engine performance without needing to be physically present at the vehicle. The remote ECM tuning service can program engines individually for improved efficiency and performance. Using diagnostic tools and Caterpillar specific software the ECM can be accessed and reprogrammed remotely to disable emission systems like DPF and CGI.

Here’s a simplified version of how it works:

Disable Emission Components: The first step is to modify the ECM to disable the DPF, CGI, and other emission-related components. This allows the engine to run without the restrictions these systems impose. By eliminating these components, the engine can operate more freely, improving air flow and reducing backpressure, which results in enhanced performance and efficiency.

Custom Engine Tuning: Many services also offer custom power tunes, which optimize the engine’s fuel delivery, timing, and power output. This step is crucial for tailoring the engine’s performance to specific needs, whether for increased power or improved fuel economy. Some engines, especially those with twin turbos, can even be tuned to convert to a single turbo configuration for more performance gains. This conversion can lead to a more simplified turbo system, reducing potential points of failure and maintenance requirements.

No Faults, No Downtime: Once the delete is done, the engine is calibrated to ensure no faults or errors occur related to the removed systems. This prevents any loss of engine performance or unexpected downtime. With the emissions systems disabled, the ECM is reprogrammed to avoid triggering fault codes, ensuring that the engine runs smoothly without interruptions. This step is critical for maintaining operational reliability, especially in demanding work environments where downtime can be costly.

What You Need for Remote Tuning

Remote tuning for Caterpillar engines requires a few tools:

- Diagnostic Adapter: A device like a Nexiq USB Link or CAT Comm that allows a connection between the engine and the tuning software.

- Caterpillar ET Software: This software is needed to interface with the ECM and make the necessary adjustments.

- Laptop: Running a Windows operating system, typically Windows 7 through 11.

- Internet Connection: Since the tuning is done remotely a stable internet connection is required for data transfer between the technician and the ECM

- Sensors play a crucial role in monitoring and managing the emissions systems, and they are integral for optimizing the performance and compliance of machines like the Caterpillar and Terex models. Once you have these tools in place you can start the remote tuning process. For many operators the ability to do this without having to take the engine to a physical shop is a big plus.

Caterpillar Engine Models Supported for DPF Delete

A detailed list of Caterpillar engine models supported for DPF and CGI delete services is provided below:

- C13 LEE ACERT + DPF + CGI

- C15 SDP ACERT + DPF + CGI

- CT13 CATFORCE (MaxxForce)

- C15 Machinery & Industrial

Each of these models is equipped with advanced features designed to maximize performance while minimizing emissions. However, the integration of Caterpillar DPF and CGI systems can sometimes impede the engine’s full potential. By opting for a Caterpillar DPF delete, owners of these engines can experience significant improvements in power output and fuel efficiency.

Moreover, the ability to convert from twin turbos to a single turbo configuration is particularly appealing for those seeking to streamline their engine’s operations. This conversion not only simplifies the turbo system but also enhances the engine’s reliability by reducing potential points of failure.

It’s important to note that while the Caterpillar DPF delete offers numerous performance benefits, it is crucial to ensure that the modification is carried out by experienced professionals. The process involves intricate adjustments to the Engine Control Module (ECM) software, which requires a deep understanding of Caterpillar engines and their unique specifications.

For those considering this upgrade, it is advisable to consult with a reputable service provider who can offer comprehensive guidance and support throughout the process. This ensures that the engine maintains optimal performance and complies with relevant regulations.

In conclusion, the Caterpillar DPF delete and CGI removal services for Caterpillar engines provide a viable solution for operators looking to boost their machinery’s capabilities. With the right expertise and tools, these modifications can lead to enhanced engine performance, reduced maintenance costs, and increased operational efficiency.

These engines are in heavy machinery and the delete services will give you a big performance boost. For some models you can also request to convert twin turbos to single turbo for better efficiency.

Real World Results with Remote DPF Delete Services

From my experience providing remote DPF delete services for many Caterpillar engines has been very successful. Many others have faced similar challenges and have benefited from the remote DPF delete services. The key is to have a proven process to ensure the engine runs smooth after the emissions components are disabled. Customers see immediate performance and fuel efficiency gains after the service is done.

One of the biggest advantages we’ve seen is to be able to offer this service online or remotely, so customers don’t have to move their machinery to a shop. This reduces downtime and gives flexibility to operators in remote areas or with large fleets of machinery.

Cat DPF Compatibility

When it comes to DPF delete technology, compatibility is essential. Engine owners need to ensure that their Caterpillar model is compatible with a dpf delete kit before installation. In this section, we will explore the importance of ensuring compatibility with various Caterpillar models and how to choose the right dpf delete kit for your engine.

Ensuring Compatibility with Various Caterpillar Models

Ensuring compatibility with various Caterpillar models is crucial when it comes to DPF delete technology. A caterpillar dpf delete kit must be designed to work with specific Caterpillar models, including cat skid steer and caterpillar engine models. By choosing a kit that is compatible with your engine, you can ensure safe and effective installation, improving fuel economy and increasing power.

It’s also important to consider the type of dpf filter used in your engine, as well as the software and programming required to eliminate the DPF. By working with a reputable supplier, you can ensure that your dpf delete kit is designed to work with your specific Caterpillar model, providing improved performance and efficiency.

Conclusion

Today, the field of diesel maintenance and performance enhancements is evolving rapidly, offering advanced solutions like DPF deletes and remote ECM tuning.

For Caterpillar engine owners who are experiencing performance issues or high maintenance costs due to DPF and CGI systems, DPF delete and remote ECM tuning is the solution. By disabling the emissions systems and optimizing the engine performance with custom software tuning, you will get better fuel efficiency, less downtime, and more power.

Whether you have a C13, C15, or MaxxForce engine, remote tuning services are available for you. These services are reliable, cost-effective, and can be done remotely so your machinery will be productive with minimal interruptions.

In summary, removing the DPF and CGI systems is a game changer for Caterpillar engines and will give you immediate and long-term benefits for years to come.

Contact Us

+51966080192

DPF SOLUTIONS